Wheel bearings....

Wheel bearings....

I'm about to put on a new tire, and thought I should replace the wheel bearings on the back. My bike is an '06 BB.

Anyone know the partnumber for the rear wheel bearings? The Boss Hoss part number likely won't do me any good, as I will likely pick them up at our local bearing supply outlet.

Thanks Guys.

Anyone know the partnumber for the rear wheel bearings? The Boss Hoss part number likely won't do me any good, as I will likely pick them up at our local bearing supply outlet.

Thanks Guys.

Re: Wheel bearings....

Hi Ric,

I made some researches on the wheel bearings. Like Adrian posted on the other site, the bearing type and size giving numers are RLS 10.

There are different suffixes behind the number, and I still don't know what "AS" means by that specific manufacturer, but what we have in our bikes is a "2Z" or "double Z" type bearing. It is "double shielded".

Another suffix behind the numers is "2RS" which means "double sealed".

I might give the double sealed type bearings (RLS 10 2RS) a try next time I change the bearings because of the bad experience I made with the "double shielded", type I use now. As I wrote on the other site, my rear wheel bearings loose grease.

Olaf

PS: I talked to our bearing supplier and described the "other way to install the bearings to the Boss Hoss"....you know what I'm talking about. He said, if you wanna make as less kilometers as possible with them, do it that way. He said an excessive force like that on the inner bearing would destoy them for sure and they won't last long. He's a SKF dealer for 20 years....

I made some researches on the wheel bearings. Like Adrian posted on the other site, the bearing type and size giving numers are RLS 10.

There are different suffixes behind the number, and I still don't know what "AS" means by that specific manufacturer, but what we have in our bikes is a "2Z" or "double Z" type bearing. It is "double shielded".

Another suffix behind the numers is "2RS" which means "double sealed".

I might give the double sealed type bearings (RLS 10 2RS) a try next time I change the bearings because of the bad experience I made with the "double shielded", type I use now. As I wrote on the other site, my rear wheel bearings loose grease.

Olaf

PS: I talked to our bearing supplier and described the "other way to install the bearings to the Boss Hoss"....you know what I'm talking about. He said, if you wanna make as less kilometers as possible with them, do it that way. He said an excessive force like that on the inner bearing would destoy them for sure and they won't last long. He's a SKF dealer for 20 years....

- Steve Taylor

- Posts: 244

- Joined: Mon Jan 19, 2009 12:50 pm

Re: Wheel bearings....

2RS means rubber sealed which are better than Z which means metal shielded, hope this helps.

Re: Wheel bearings....

I wonder, Olaf, .... if one might machine an outer spacer for our bikes to act as a 'push tool' and it would be left in the wheel like the inner spacer. I can't see any harm in that, and the bearing would survive, in my opinion.

Just a thought.

Just a thought.

Re: Wheel bearings....

Ric,Ric wrote:I wonder, Olaf, .... if one might machine an outer spacer for our bikes to act as a 'push tool' and it would be left in the wheel like the inner spacer. I can't see any harm in that, and the bearing would survive, in my opinion.

Just a thought.

not sure if I understand right. The outer spacers and the inner (long) spacer tube must have the contact area at the inner bearing to spin free.

But a push tool should have contact and apply force to the outer bearing surface only. If one would leave it inside the wheel, wouldn't it lock up the front axle?

If I misunderstood you, could you make a drawing for better understanding and post it?

What I thought about, is machining one cupped spacer (press tool) and two flat spacers. The brake rotor side bearing (the one with the shoulder) can be pressed in all the way with the press tool. The pulley side (without shoulder) bearing could be pressed in with the same press tool, too. But not all the way, just enough to seat straight in the bore.

Now, if one would machine two more, totally flat spacers (grinded surface would be good), which put evenly force to the inner and outer bearing at the same time. And one would pull the left bearing into the bore, maybe with a threaded rod and these two flat grinded spacers until it sits tight to the inner spacer tube....I think that should work. but not 100% sure - I have to try it this way first. Oh man, my english is bad....hahahaha...I edited about 50 times even before I hit "submit"...hahaha...

Olaf

Re: Wheel bearings....

KrautV8 wrote:Ric,Ric wrote:I wonder, Olaf, .... if one might machine an outer spacer for our bikes to act as a 'push tool' and it would be left in the wheel like the inner spacer. I can't see any harm in that, and the bearing would survive, in my opinion.

Just a thought.

not sure if I understand right. The outer spacers and the inner (long) spacer tube must have the contact area at the inner bearing to spin free.

But a push tool should have contact and apply force to the outer bearing surface only. If one would leave it inside the wheel, wouldn't it lock up the front axle?

If I misunderstood you, could you make a drawing for better understanding and post it?

What I thought about, is machining one cupped spacer (press tool) and two flat spacers. The brake rotor side bearing (the one with the shoulder) can be pressed in all the way with the press tool. The pulley side (without shoulder) bearing could be pressed in with the same press tool, too. But not all the way, just enough to seat straight in the bore.

Now, if one would machine two more, totally flat spacers (grinded surface would be good), which put evenly force to the inner and outer bearing at the same time. And one would pull the left bearing into the bore, maybe with a threaded rod and these two flat grinded spacers until it sits tight to the inner spacer tube....I think that should work. but not 100% sure - I have to try it this way first. Oh man, my english is bad....hahahaha...I edited about 50 times even before I hit "submit"...hahaha...

Olaf

I wouldn't worry about your English Olaf ... I understand what your saying and it sounds like your idea should work.

Don

PS

If I had to write this in German I'd still be "editing"

IF YOU TELL THE TRUTH YOU DON'T HAVE TO REMEMBER ANYTHING

Re: Wheel bearings....

Olaf....

You are a genius! After some thought, I realized that my idea of two spacers, inner and outer to press on the bearings would certainly lock up the outer 'ring'... as the compression force of the spacer left inside would not work.

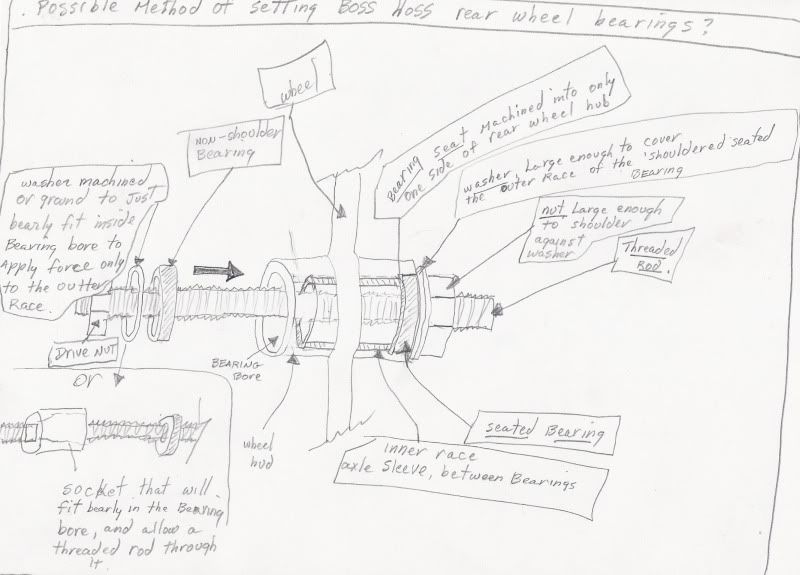

But your thoughts on a 'threaded press'... where you have two washers (actually, you only need one fit to the bearing outer race bore), machined or ground just under the bore of the wheel's bearing side. Go ahead and press the 'shouldered' bearing into place. Put the spacer in the wheel, then place your 'non shouldered' bearing in place... making sure it's going in absolutely straight... put your 'threaded press' (large flat washer on the seated bearing... threaded rod through the wheel (The threaded rod of course easily fits inside the inner race, through to the other side beyond the next bearing). Place your 'non-seated' bearing over the threaded rod, and into the bearing bore on the otherside of the wheel. Then slip the machined or grounded washer over the shoulders of the outside of the bearing... then thread a nut over the rod until it seats on the 'drive washer'. Sloooooooooowly crank in the bearing as the washer will press on the outer race... until it's seated against the inner axel spacer.

Brilliant! This gives you more control over how the bearing is being seated by hand threading, rather than hydraulic force.

Oh... and even though you 'edited' your idea.... because of language issues... I'm thinking we'd have easily caught what you meant the first post you'd have sent.

You are a genius! After some thought, I realized that my idea of two spacers, inner and outer to press on the bearings would certainly lock up the outer 'ring'... as the compression force of the spacer left inside would not work.

But your thoughts on a 'threaded press'... where you have two washers (actually, you only need one fit to the bearing outer race bore), machined or ground just under the bore of the wheel's bearing side. Go ahead and press the 'shouldered' bearing into place. Put the spacer in the wheel, then place your 'non shouldered' bearing in place... making sure it's going in absolutely straight... put your 'threaded press' (large flat washer on the seated bearing... threaded rod through the wheel (The threaded rod of course easily fits inside the inner race, through to the other side beyond the next bearing). Place your 'non-seated' bearing over the threaded rod, and into the bearing bore on the otherside of the wheel. Then slip the machined or grounded washer over the shoulders of the outside of the bearing... then thread a nut over the rod until it seats on the 'drive washer'. Sloooooooooowly crank in the bearing as the washer will press on the outer race... until it's seated against the inner axel spacer.

Brilliant! This gives you more control over how the bearing is being seated by hand threading, rather than hydraulic force.

Oh... and even though you 'edited' your idea.... because of language issues... I'm thinking we'd have easily caught what you meant the first post you'd have sent.

Re: Wheel bearings....

Is this is what you are getting at Olaf? If you see flaws in it... please offer your ideas... that's why we share this site... to make thing easier for us all.

Thanks m'man!

Re: Wheel bearings....

Ric,

The drawing is perfect! That's what I meant. It could work. Additionally I would do the following:

after the bearings are pressed in, I would put the rear axle with the original spacers thru the wheel (without installing the wheel to the rear swing arm), then I would tighten the axle nut in very small steps, maybe 5 ft·lb steps or less, to the required torque specs....(60, 80 ft·lb? - I don't have the manual handy)...., just to check by hand if the assembly spins free at every torque step and finally when fully tightened. If the axle spins harder during the process, you need to press in the unshouldered bearing a little deeper and try again.

You will be most likely the first one who tests if it works this way or not, cause I bought a bearing, pulled out the shields and changed only one to my bike. My bearings are fine, not many miles on them. I was only worried about them and wanted to change them because one were throwing grease all over the place. The left side (brake rotor side) was worst. That's hopefully fixed now with the new shield and repacked. I think the other side was "normal" since I have read they always loose a little grease during brake in.

Let me know if it works, so I can prepare everything for the day when I have to change them.

Thanks,

Olaf

The drawing is perfect! That's what I meant. It could work. Additionally I would do the following:

after the bearings are pressed in, I would put the rear axle with the original spacers thru the wheel (without installing the wheel to the rear swing arm), then I would tighten the axle nut in very small steps, maybe 5 ft·lb steps or less, to the required torque specs....(60, 80 ft·lb? - I don't have the manual handy)...., just to check by hand if the assembly spins free at every torque step and finally when fully tightened. If the axle spins harder during the process, you need to press in the unshouldered bearing a little deeper and try again.

You will be most likely the first one who tests if it works this way or not, cause I bought a bearing, pulled out the shields and changed only one to my bike. My bearings are fine, not many miles on them. I was only worried about them and wanted to change them because one were throwing grease all over the place. The left side (brake rotor side) was worst. That's hopefully fixed now with the new shield and repacked. I think the other side was "normal" since I have read they always loose a little grease during brake in.

Let me know if it works, so I can prepare everything for the day when I have to change them.

Thanks,

Olaf

Re: Wheel bearings....

Yes Olaf... I had the bearings pressed out today... and believe the 'shouldered' side in on the brake rotor side of the wheel.

I spent the afternoon using 'sand cloth' (a sand paper that resembles bug screen with abrasive surface on it) to score my wheel rims, and hub assembly parts as well... to prepare the wheels to be powder coated gloss black. Because a stock BH wheel is polished aluminum... it needs a rougher surface for the powder coating to adhere to.

About six months ago, I replaced the front wheel bearings that I purchased from the local Harley Davidson dealer as I was told that the Harley Road King front bearings were the same. And I also paid the overpriced dollars for them too! $54.00 Canadian for each bearing. And when we pressed them out of the hubs today... my machinist buddy said that I should replace them again, as he had to press the inner race to get them out of the hub assembly. I guess, for safety sake... I'll do that.

But the Powder coating process will take about a week, and between waiting for the parts to come back, and the crazy work schedule I have... I'll find the time to make up the tool we spoke of... and I'll try your 'test method' before I mount the wheel in the bike.

I'll keep you posted.

I spent the afternoon using 'sand cloth' (a sand paper that resembles bug screen with abrasive surface on it) to score my wheel rims, and hub assembly parts as well... to prepare the wheels to be powder coated gloss black. Because a stock BH wheel is polished aluminum... it needs a rougher surface for the powder coating to adhere to.

About six months ago, I replaced the front wheel bearings that I purchased from the local Harley Davidson dealer as I was told that the Harley Road King front bearings were the same. And I also paid the overpriced dollars for them too! $54.00 Canadian for each bearing. And when we pressed them out of the hubs today... my machinist buddy said that I should replace them again, as he had to press the inner race to get them out of the hub assembly. I guess, for safety sake... I'll do that.

But the Powder coating process will take about a week, and between waiting for the parts to come back, and the crazy work schedule I have... I'll find the time to make up the tool we spoke of... and I'll try your 'test method' before I mount the wheel in the bike.

I'll keep you posted.

Re: Wheel bearings....

Hey Olaf...

Just thought about the test method of assembling the axle and spacers out of the swingarm.

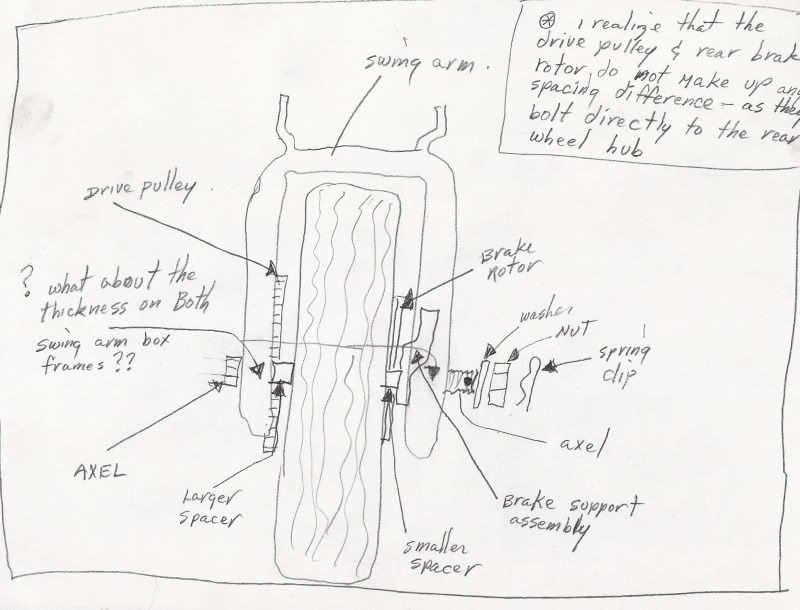

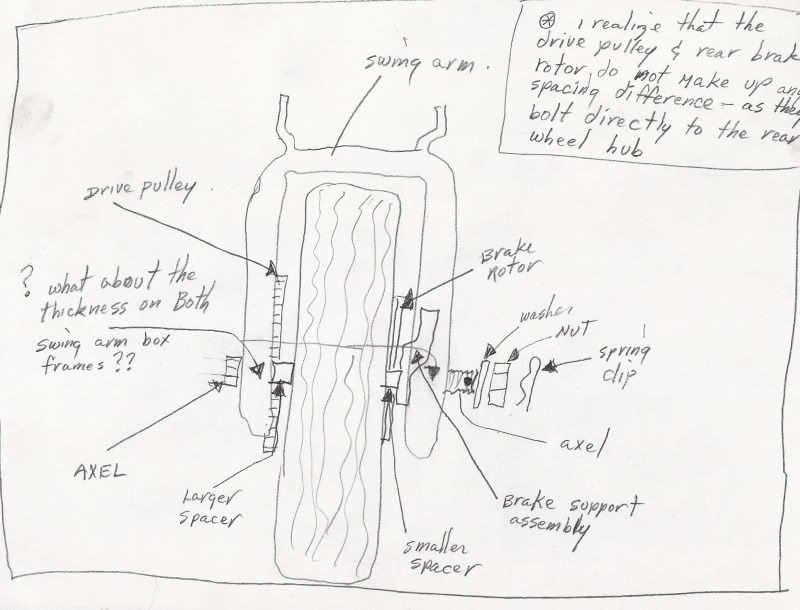

I've only had my wheel apart one time prior to this... but don't we need a physical 'additional' set of spacers to compensate for the swing arm not being there? I mean, the swing arm makes up part of the complete spacing for the whole axle train, does it not? I'm trying to picture the axle, trying to remember if it has shoulders cut into it that make up the swing arm box frame on both sides...

I also think that if the wheel and axel/spacer assembly is bolted together off of the bike, we not only don't have both swing arm box frame spacing... but also the Brembo brake support spacing that goes between the small spacer on the right side, and the swing arm.

With those three elements gone... can we still perform the check you are thinking about?

Sometimes I wish my computer was right beside my bike when addressing some of the tech talk we discuss online.

Here's a pic of what I mean....

Just thought about the test method of assembling the axle and spacers out of the swingarm.

I've only had my wheel apart one time prior to this... but don't we need a physical 'additional' set of spacers to compensate for the swing arm not being there? I mean, the swing arm makes up part of the complete spacing for the whole axle train, does it not? I'm trying to picture the axle, trying to remember if it has shoulders cut into it that make up the swing arm box frame on both sides...

I also think that if the wheel and axel/spacer assembly is bolted together off of the bike, we not only don't have both swing arm box frame spacing... but also the Brembo brake support spacing that goes between the small spacer on the right side, and the swing arm.

With those three elements gone... can we still perform the check you are thinking about?

Sometimes I wish my computer was right beside my bike when addressing some of the tech talk we discuss online.

Here's a pic of what I mean....

Re: Wheel bearings....

Ric,

Aaaaaah....yes, you are right! The swing arm boxes and the brake rotor have to be compensated, cause the thread is not very long on that rear axle. I think an additional, single, long spacer on one side would be enough to do the job. I made all my spacers (old and new bike) from stainless steel, so I have lots of old stock spacers laying around and could use them.

Good that you reminded me that the bearings have to be out for powder coating!! I too plan to powder coat my wheels black next winter, so I have to wait with the new bearings anyway. Like you said before....it's so nice to have this board (and the .com site). We can so much learn from each other. It would be a desaster if I would have pressed in new bearings and have to throw them out a couple of month later...puuuhh....

Olaf

Aaaaaah....yes, you are right! The swing arm boxes and the brake rotor have to be compensated, cause the thread is not very long on that rear axle. I think an additional, single, long spacer on one side would be enough to do the job. I made all my spacers (old and new bike) from stainless steel, so I have lots of old stock spacers laying around and could use them.

Good that you reminded me that the bearings have to be out for powder coating!! I too plan to powder coat my wheels black next winter, so I have to wait with the new bearings anyway. Like you said before....it's so nice to have this board (and the .com site). We can so much learn from each other. It would be a desaster if I would have pressed in new bearings and have to throw them out a couple of month later...puuuhh....

Olaf

Re: Wheel bearings....

Just keep it in mind that powder coating can vary in thickness but is usually at least .020 thick so all critical surfaces on your wheels need to be masked or covered in some way so there is no powder coat build up . When I had my wheels powder coated I made up plates to mask the wheel surfaces that the hubs bolt to .

Just a note about choosing gloss black or semi gloss black . Wheels are almost always dusty . Gloss black shows dust more than semi gloss . Semi gloss black is still shinny but has a dusty tint to it . I had mine done in semi gloss and like it a lot .

Jack

Just a note about choosing gloss black or semi gloss black . Wheels are almost always dusty . Gloss black shows dust more than semi gloss . Semi gloss black is still shinny but has a dusty tint to it . I had mine done in semi gloss and like it a lot .

Jack

Re: Wheel bearings....

hogv8 wrote:Just keep it in mind that powder coating can vary in thickness but is usually at least .020 thick so all critical surfaces on your wheels need to be masked or covered in some way so there is no powder coat build up . When I had my wheels powder coated I made up plates to mask the wheel surfaces that the hubs bolt to .

Just a note about choosing gloss black or semi gloss black . Wheels are almost always dusty . Gloss black shows dust more than semi gloss . Semi gloss black is still shinny but has a dusty tint to it . I had mine done in semi gloss and like it a lot .

Jack

Good point Jack,

I'm a trailer trash type rider, I kept the bike well maintained... and actually ride the bike when it's dirty after it sat in the shop from a previous rainy muddy ride. I never polished my aluminum rims since I got the bike. Long way to reach for something you can hardly see with the large rear pully and brake rotor on the oposing side. So they looked a 'little dusty' to even the casual viewer. I think the pressure washer at the car wash will make gloss 'albeit dusty' black wheels look much better than the shit that was clinging to the aluminum rims and hubs from only pressure washing.

Because I ride in rain, slush and often snow... the times the bike gets a good gleeming session is when we know we are getting a day or two of sun. But because it's a daily rider, It gets a quick shower in the morning, just like me when I get up to go to work....

Re: Wheel bearings....

Andy from BH Germany had his wheels black anodized. Looks great and lasts long.

Just another option...

Olaf

Just another option...

Olaf